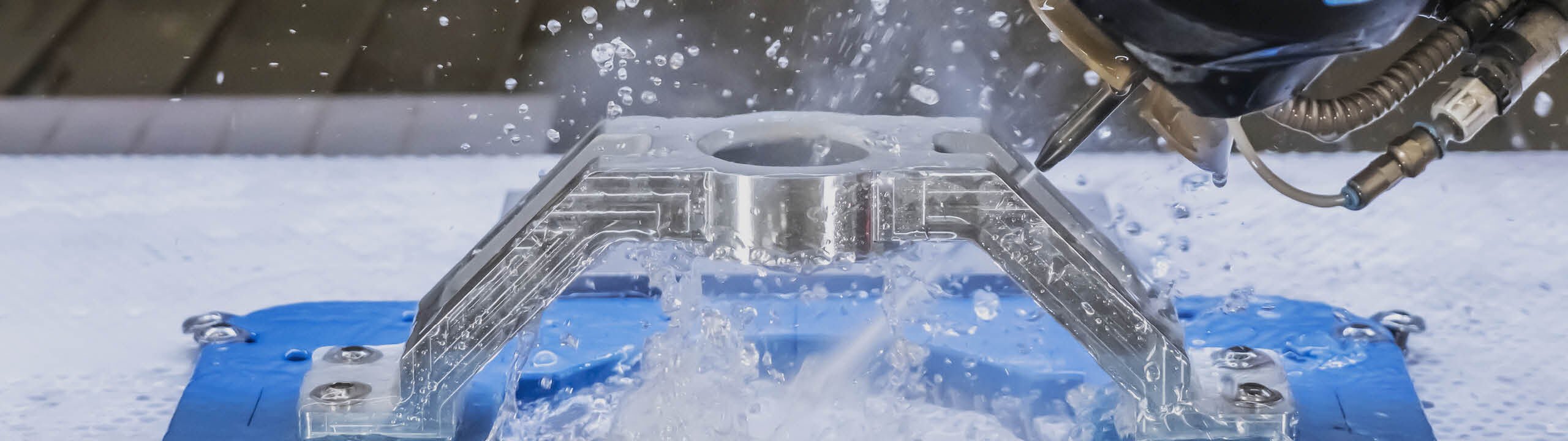

The CMS JD5plus 5-axis head is the most effective way of expanding the application range of a waterjet from 2D to 3D cutting immediately, safely and with lower tooling times. The combination of the Plug&Play prober, safe axis control and abrasive filtration designed for challenging environments maximize uptime and cutting quality, while guaranteeing a return on investment right from the first jobs.

Thanks to the experience of CMS Metal Technology and the reliability of robust, modular structures with large worktables, CMS solutions guarantee clean, precise and repeatable cuts on a wide variety of materials. From the machining of the hardest metals to the most delicate and composite materials, CMS waterjet technology stands out for its precision, versatility and efficiency.

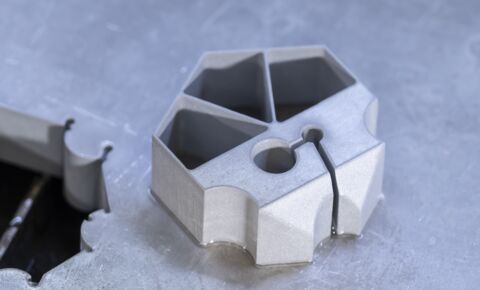

With both abrasive and pure waterjet technology, the compact version of CMS tecnocut smartline is designed to meet the needs of rapid prototyping and small batch production. This solution is particularly suitable for research centers, prototyping laboratories, small mechanical workshops, and companies that fabricate with metals, composites, plastics and rubber.