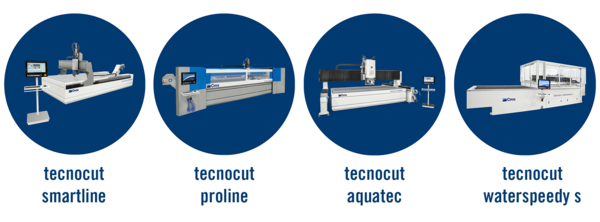

Thanks to the experience of CMS Metal Technology and the reliability of robust, modular structures with large worktables, CMS solutions guarantee clean, precise and repeatable cuts on a wide variety of materials.

From the machining of the hardest metals to the most delicate and composite materials, CMS waterjet technology stands out for its precision, versatility and efficiency.

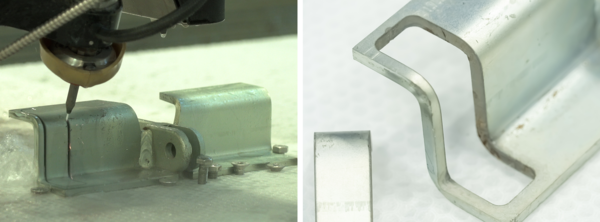

Waterjet machines are capable of effectively cutting all types of metals. The result is a precise cut, with smooth edges, free of structural alterations and excess burrs. Moreover, being a cold process, no heat-affected zones are generated, preserving the material's integrity.

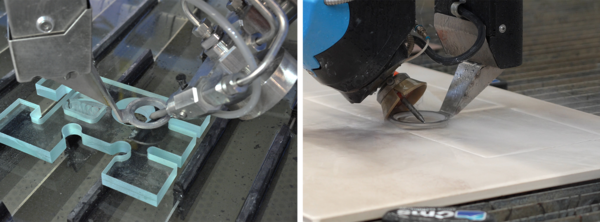

Abrasive waterjet cutting is the ideal solution for machining carbon fiber and all multilayer materials. It does not require tool replacement, eliminates issues related to heat buildup, and the absence of harmful fumes and dust avoids the need for costly air extraction and filtration systems.

Thanks to its ability to easily and precisely cut materials such as foams, rubber, and polymers, CMS waterjet cutting technology confirms itself as a high-value multi-purpose solution. Its exceptional versatility makes it an essential tool for every modern workshop.

Glass, natural stones, quartz, and ceramics: CMS waterjet machines offer maximum versatility even in the processing of these materials. Thanks to advanced techniques, it is possible to achieve precise, high-quality results on a wide range of surfaces, even the most fragile and thickest ones.

Precision without material limits: CMS waterjet solutions are the ideal answer for those seeking versatility, quality and reliability in a single solution.